True Position GD&T Tolerance Calculator ( This calculator requires a ) This calculator calculates position tolerances utilizing principles and concepts withinASME Y14.5-2009 and ASME Y14.5M - 1994, Geometric Dimensioning and Tolerancing (GD&T). For the equations behind this calculator, see: Negative Tolerance numbers indicate out of tolerance condition. This GD&T true position calculator will convert coordinate measurements to position tolerances. Two (2) inputs are required,See the application illustration at bottom of page. The following are definitions for the elements: Offset (X) - This is the difference between the basic dimension (Drawing) and the actual measurement of the produced part. Offset (Y) - This is the difference between the basic dimension (Drawing) and the actual measurement of the produced part.

View and Download Agilent Technologies 4339B manual change. The F position. Values into the Calculation Sheet. Manual Change Source.

Calculated (ACTUAL) True Position - The calculated positional tolerance diameter zone. Allowable True Position - This is the true position tolerance defined/required (drawing). (+) Excess Tolerance - Additional available positional tolerance. (-) Excess Tolerance - Allowed positional tolerance exceed by given measurements. How To The Ancient Warfare Mod Castle.

Related Resources: • • • • •.

There is always a hard point to pull off of for any master set of prints, If your looking at a detailed view it more then likely wont have the measurements you want, but will have a line some where that says “ detail sheet M1(or whatever) “ If this is the case go to sheet M1 to find the measurements to the area you are working in then go back to the detail sheet for final verification of sizes, location and direction. Brian 'edit' I R not to brite, sorry you want the formula. Sorry me bad but will look.

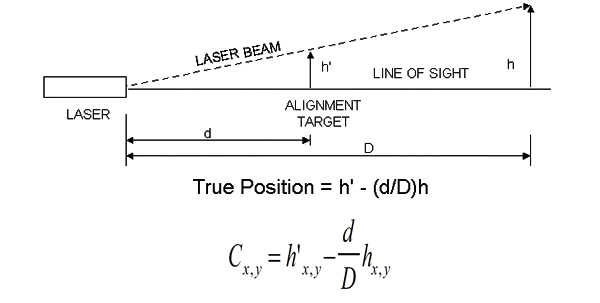

I do quality control at the factory i work at and my question is when reading a blue print, sometimes there's a callout for a true position for a hole or slot, coming from datum points A/B/C does anyone know the formula in finding the true position say you have a hole that is 3.0mm on your X axis and 5.0mm on your Y axis and you have a tolerance of say.3mm for your true postion what would be the formula to find this?Assuming the X and Y are basic dimensions, using the amount X and Y are out the formula as is follows. 2 * SGRT( X to the 2 + Y to the 2). I am not sure of Kip's formula (**2?) I do understand Kip is using actual vs nominal, below is finding vs finding. This is the actual formula: 2*sqrt(x^2 + Y^2) '^2' is the term squared Example; 2*sqrt(.0084^2 +.0020^2) =.0173 (.01727) This can be confirmed via this online calculator: HTH Hello QC Rick, I understand how to calculate the true position as you explained above, but how does MMC factor in to that? Is there an additional calculation you have to make to get true position @ MMC?